Process facilities of the ORLEN Group are properly designed, built, operated, repaired, maintained and upgraded. They also conform to the highest standards and meet the requirements of all laws, regulations and rules.

Process safety

≤0,3

T1 PSER maintained for the ORLEN Group

3

number of spills at the ORLEN Group in 2022*

ok. 31 Mg

mass of spills in 2022* Sustainable

* The reported indicators do not include data for the former LOTOS Group and PGNiG Group. Indicators based on full data will be reported for 2023.

- 11.8.1

Management of material topic: asset integrity and critical incident management

Process safety management and policies in place

Overview

The Process Safety Office is engaged in the oversight of the Safety Management System at ORLEN and provides relevant support to the ORLEN Group companies.

For SEVESO Establishments at ORLEN, the Process Safety Office monitors compliance with the legal requirements and other regulations on major industrial accidents within its remit.

The Office is also involved in promoting and advancing the culture and idea of process safety, implementing and promoting best practice in safety management, and providing directions for the development of process safety across the ORLEN Group. The Office collaborates with universities to raise the awareness of process safety.

Asset integrity and critical incident management

Process safety – activities involving definition of methods and measures to protect people and the environment against the consequences of failures and industrial accidents; identification of existing needs before technological, process or organisational changes; organisational and technical measures undertaken at every stage of a process to guarantee safe process management, safety of the process personnel, and thus process reliability.

Any identified potential accident hazard at the ORLEN Group’s plants is likely to have an adverse impact on:

- The environment, if hazardous substances are released into the atmosphere or into the soil and groundwater in unpaved areas.

- There is also a potential threat to the health and life of employees, contractors and individuals subjected to physical exposures (such as thermal radiation, overpressure wave or toxic gas cloud) from industrial accidents.

- Impacts on human rights are effectively minimised through the implementation of Policies and standards aimed at protecting human rights at the ORLEN Group. The goals and objectives of these Policies and standards demonstrate that they prioritise protection of the health and safety of ORLEN Group employees as an overriding value, an essential element of the ORLEN Group’s organisational culture and business ethics, and a reflection of its commitment to fundamental human rights. The ORLEN Group provides a safe and healthy work environment for all its employees, making every effort to ensure that the workplace is free of health and life hazards and organised so as to protect employees against injuries and serious health impairment. The Group makes efforts across three dimensions, by fostering a safety culture, developing personal and process safety, and taking a range of measures aimed at preventing workplace injuries, industrial accidents, fires and other unwanted incidents.

Business relationships for the identification and reporting of process safety events at the ORLEN Group are based on the requirements of the countries in which the plants are located. In countries of the European Union, the leading regulation for process safety events is Directive 2012/18/EU of the European Parliament and of the Council of 4 July 2012 on the control of major accident hazards involving dangerous substances, amending and subsequently repealing Council Directive 96/82/EC (the SEVESO Directive). Each EU member state has implemented the requirements of that Directive into its national law. Accordingly, relationships with respect to process safety events are built between plant operators and competent authorities (public authorities). Based on its activities and experience to date, such relationships at the ORLEN Group are built in a competent and responsible manner, with due respect for human rights and freedom of expression on both sides.

In an effort to prevent major industrial accidents at the ORLEN Group, relevant Policies have been put in place, some of them based on the requirements of the SEVESO Directive. The Directive obligates plant operators to draw up a major accident prevention policy and submit it to the competent authorities. ORLEN has met this requirement, drawing up an equivalent of such policy: the Declaration on Prevention of Major Industrial Accidents at Polski Koncern Naftowy ORLEN Spółka Akcyjna. The Declaration sets out the operator’s overall approach and measures, including appropriate safety management systems, for controlling major accident hazards.

To manage the topic of process safety events at the ORLEN Group, each company has adopted relevant Internal Orders and Procedures (mechanisms) for activities involving identification, response, reporting and handling of such events, as well as remedying the damage and restoring the plant to normal operation.

The ORLEN Group’s production companies have implemented a Process Safety Management System conforming to the US OSHA 1910.119 standard, taking into account the Guidance on meeting expectations of The Energy Institute Process Safety Management Framework. The system provides an effective framework for achieving operational excellence, as it improves technical safety of the process, storage and auxiliary units, and thus prevents any unwanted incidents that could affect the safety of staff and/or production processes. The Process Safety Management System, as a component of ORLEN’s overall management and organisational system, was introduced to ensure the highest safety standards in the workplace and meet the national requirements of Art. 252 of the Environmental Protection Law of April 27th 2001 (consolidated text: Dz.U. of 2022, item 2556, as amended) with respect to systemic process safety management and further improvement of the effectiveness and efficiency of measures aimed at preventing major industrial accidents.

In addition, mechanisms were developed and implemented to allow various teams involved in an incident investigation to make recommendations aimed at preventing reoccurrence of similar incidents at the ORLEN Group and to share knowledge through lessons learned.

These include:

- Use of dedicated and internationally recommended hazard analysis and process risk assessment methods, i.e. HAZOP, QRA, PHA, evaluation of physical effects of identified possible accident scenarios at the design stage and during the use of installations presenting accident hazards. Adoption of technical measures at the ORLEN Group facilities to detect and quickly respond to any unplanned events, as well as maintenance of Company Fire Brigades within the structures of the ORLEN Group plants, which significantly contribute to the mitigation of potential negative impacts.

- Implementation of Procedures and allocation of responsibilities to individual areas responsible for cooperation with external authorities, inspection bodies and accident investigation authorities appointed by the governments of the countries where the ORLEN Group plants are located. Establishment of mechanisms to determine the scope and type of information to be shared outside in order to investigate accidents, request corrective action or remedy the consequences.

- Development and implementation at the ORLEN Group of mechanisms of cooperation with public authorities and external institutions for drills carried out to test the effectiveness of internal procedures on the basis of applicable national legislation.

In order to monitor the effectiveness of measures addressing safety incidents at the ORLEN Group, the following have been implemented:

- Relevant Standards of Practice, such as: ST S6 T1 ‘Reporting of personal, fire and process safety incidents at the ORLEN Group’, ST M1 T3 ‘Technical Standard for Management of Personal and Process Safety Metrics at the ORLEN Group’. On that basis, information about any incidents at the ORLEN Group is reported to ORLEN. The information is used to generate reports summarising key process safety metrics on a monthly, semiannual and annual basis, as well as for individual internal needs or for external auditors.

- The ORLEN Group’s key process safety indicator is T1 PSER. The aspirational trend curve for this indicator for 2022–2026 has been defined in the ‘ORLEN Group Development Directions in Personal and Process Safety’. In addition to this indicator, there are other metrics, which are described in detail in the aforementioned ST M1 T3 standard.

- The effectiveness of measures taken and progress towards the stated goals are recorded on a year-on-year basis and reviewed against the objectives of the ‘Development Directions’. Reports summarising the values of key indicators are prepared annually. On that basis, collaboration within the ORLEN Group is furthered and lines of action are defined to improve the existing Process Safety Management Systems.

- Conclusions drawn from the process safety indicators are reported and communicated within the ORLEN Group by email and during annual ORLEN Group’s Personal, Process and Fire Safety Personnel Meetings. The target indicators for future reporting periods are always analysed and communicated to ORLEN Group companies.

- Stakeholder involvement may significantly contribute to indicator values thanks to appropriate classification of safety events in accordance with the ORLEN Standard. The objectives set in the ‘ORLEN Group Development Directions in Personal and Process Safety’ will help improve the existing Process Safety Management Systems and deploy one at the remaining plants. The effectiveness of measures taken to improve Process Safety Management Systems at the ORLEN Group is best demonstrated by the fact that the T1 PSER indicator for the ORLEN Group has been maintained at ≤ 0.3, matching the aspiration line.

Due diligence procedures

In 2022, work was carried out to maintain and improve the Process Safety Management System based on OSHA 1910.119 standard. It provides a more effective framework for achieving operational excellence, as it guarantees technical safety of the process, storage and auxiliary units, and thus prevents unwanted events that could affect the safety of staff or processes.

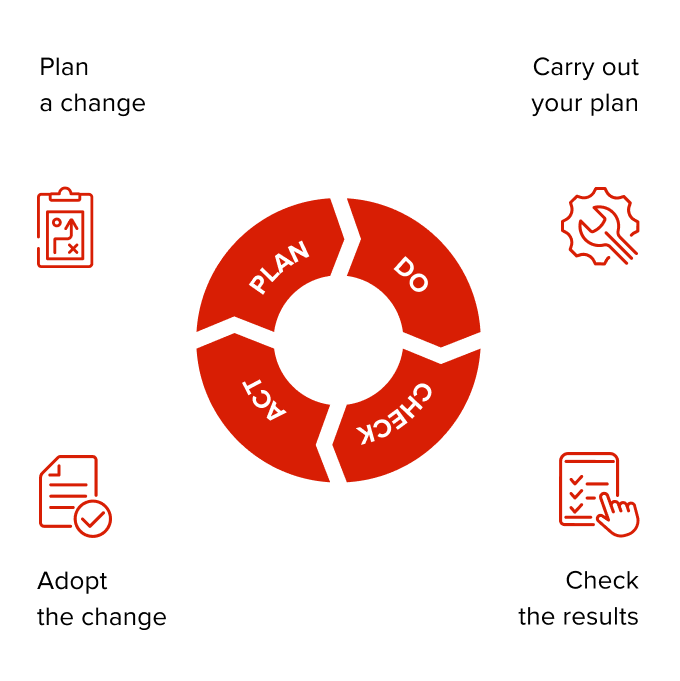

As part of maintenance and improvement of the Process Safety Management System, the following steps are required in accordance with the Deming cycle:

- Review the status quo;

- Check the existing regulations / internal policies for completeness and put in place new ones;

- Confirm that each system component has been fully implemented;

- Satisfy the system requirements based on regulations / policies and make the necessary improvements.

The review covers the company’s compliance with the requirements for 14 components of the Process Safety Management System under existing regulations by which a given component has been implemented.

Components of the Process Safety Management System:

Process safety is becoming a specific field related to resilience engineering, which defines safety as the ability to maintain plant success under normal and emergency conditions. An important role is played by organisational systems, capable of immediate response to maintain business continuity.

29 plants/facilities of the ORLEN Group were classified as upper-tier establishments in 2022, and almost half of that number as lower-tier establishments, as per the classification framework under the Seveso III Directive applicable across Europe and implemented into national law by all EU member states in 2015.

In Poland, the relevant regulations are laid down in the Environmental Protection Law. The establishments of both types have in place advanced and constantly improved process safety management systems as an organised method for managing safety, encompassing all the vital safety components referred to above.

To describe the current status of process safety at the ORLEN Group production companies, the Group uses various process safety indicators, including leading and lagging ones, in accordance with the API 754 standards. Those indicators are monitored and measured using the Company’s internal application to help achieve the overarching objective of process safety management, which means preventing and minimising the risk of major accidents. These indicators also serve as the basis for benchmarking against the best industry players and thus contribute to achieving process excellence.

ORLEN Group plants/facilities with a high and increased risk of a major industrial accident (uppertier and lower-tier establishments)*

- 11.8.2

Significant spills*

Total number and mass** of significant spills

Information on each spill reported by ORLEN Group companies is presented in the table below.

* The reported indicators do not include data for the former LOTOS Group and PGNiG Group. Indicators based on full data will be reported for 2023.

** Most organisational and technical documents (Emergency Manuals/SEVESO Documents) maintained by the ORLEN Group companies and the type of substances present necessitate reporting the volume of a release in Mg rather than m3. Furthermore, in line with the requirements of API 754, a substance release is determined based on thresholds expressed in units of mass. Therefore, to standardise reporting, the volume of significant spills has been reported in units of mass rather than volume.

The consequences of all of the above spills involved equipment and site contamination. In addition, most of those incidents required covering the costs of rescue operations by Company Fire Brigades as well as repair or replacement of damaged equipment. No person suffered any injuries as a result of those incidents.

- 11.8.3

Number of process safety events, by business activity

TIER 1, TIER 2 and TIER 3 process safety events*

TIER 1 PROCESS SAFETY EVENTS

These are emergencies with a significant impact related to a sudden and unexpected substance release due to ineffective protection layers. Such incidents include a sudden and unexpected release of hazardous substances or non-toxic and non-flammable substances (steam, condensate, hot water, nitrogen, compressed air, CO2) during ongoing industrial processes, having one or more of the following consequences:

- Injury to an employee of the ORLEN Group or of a contractor or subcontractor, resulting in a sick leave or death;

- Hospital admission and/or death of any other person;

- Officially announced evacuation of local residents or recommendation for them not to leave their homes;

- Fire or explosion resulting in losses in the form of direct costs of at least USD 100 thousand;

- Release of excessive pressure into the atmosphere with the use of pressure relief devices in an amount equal to or higher than the threshold amounts in any one hour period;

- Release of a substance (without causing its ignition) in an amount equal to or higher than the threshold amounts in any one-hour period, excluding release of pressure into the atmosphere with the use of pressure relief devices.

TIER 2 PROCESS SAFETY EVENTS

These are events of lesser consequence related to a sudden and unexpected substance release due to ineffective protection layers. Such emergencies include a sudden and unexpected release of hazardous substances or non-toxic and non-flammable substances (steam, condensate, hot water, nitrogen, compressed air, CO2) during ongoing industrial processes, having one or more consequences not classified as TIER1, including:

- Injury to an employee of the ORLEN Group or of a contractor or subcontractor;

- Fire or explosion resulting in losses in the form of direct costs of at least USD 2,500;

- Release of excessive pressure into the atmosphere in an amount equal to or higher than the thresholds in any one-hour period;

- Release of a substance (without causing its ignition) in an amount equal to or higher than the threshold amounts in any one-hour period, excluding release of pressure into the atmosphere with the use of pressure relief devices.

* The reported indicators do not include data for the former LOTOS Group and PGNiG Group. Indicators based on full data will be reported for 2023.

Number of TIER 1, TIER 2 and TIER 3 events at ORLEN and the ORLEN Group

Number of TIER 1 process safety events – ORLEN and the ORLEN Group

Number of TIER 2 process safety events – ORLEN and the ORLEN Group

In 2022, the ORLEN Group continued reporting the TIER 31 process safety events rate referring to nearmiss events.

Number of TIER 3 process safety events – ORLEN and the ORLEN Group

Number of process safety events at the ORLEN Group

T1 PSER indicator2 at the ORLEN Group

T2 PSER indicator3 at the ORLEN Group

2 T1 PSER = (number of TIER 1 process safety events, of greater consequence, related to substance release into the environment/ number of man-hours worked by employees and contractors) x 1,000,000

3 T2 PSER = (number of TIER 2 process safety events, of lesser consequence, related to substance release into the environment/number of man-hours worked by employees and contractors) x 1,000,000

The Two of the TIER 1 events reported for 2022 had an impact on ORLEN Group employees. One of them resulted in the deaths of two employees, while four ORLEN Group employees were injured in the other. The other TIER 1 and TIER 2 events reported for 2022 involved only emissions into the environment caused by fires and spills. There were no incidents causing serious damage to the natural environment. Liquid leaks were collected and properly disposed of.

Investigation teams were set up at ORLEN Group companies for all the reported incidents, in particular those resulting in casualties and injuries. Recommendations were made and corrective actions were taken to prevent reoccurrence.

- 11.8.4

The ORLEN Group is not involved in the oil sands business.

Read also:

Short-cuts:

ORLEN Group 2022 Integrated Report

You can also download the report in PDF format