Integrated Management System

- 3-3

Integrated Management System

To deliver on that promise, the Group has an Integrated Management System (IMS) in place.

The IMS comprises:

- Quality Management System based on the PN-EN ISO 9001 and AQAP 2110 standards;

- Environmental Management System based on the PN-EN ISO 14001 standard;

- Occupational Health and Safety Management System based on the PN-EN ISO 45001 standard;

- Energy Management System (SZEn) based on the ISO 50001 standard;

- Information Security Management System based on the PN-ISO/IEC 27001 standard;

- International Sustainability & Carbon Certification System (ISCC EU);

- Sustainability Certification System for Biomass and Biofuels (KZR INiG);

- Factory Production Control System (ZKP);

- HACCP Food Safety Management System compliant with Codex Alimentarius standard;

- Quality Management System based on the PN EN ISO/IEC 17025 standard (in place at all the organisational units which conduct research or tests using methods that require approval by the Office of Technical Inspection (UDT));

- Risk Based Inspection Management System (RBI).

The scope and rules governing the operation of the Integrated Management System are specified in:

- Integrated Management System (IMS) Book with schedules;

- Energy Management System Book;

- Factory Production Control (ZKP) Book;

- Risk Based Inspection (RBI) Book;

- JET A1 Book – supervision of quality of aviation turbine fuel during production, storage and distribution;

- PN-EN ISO/IEC 17025 System Book;

- HACCP Book;

- System procedures approved by the President of the Management Board – Chief Executive Officer/ Members of the Management Board;

- Maps, charts and metrics for the identified processes;

- Operating procedures/instructions/manuals approved by Directors/Managers for their respective processes/areas.

In 2022, the following key projects were completed with respect to the Integrated Management System:

- Cooperation with certification bodies with respect to Management Systems surveillance was continued;

- The Factory Production Control (ZKP) System certification was maintained and improved, its scope extended to cover processes carried out for ORLEN by Rafineria Gdańska Sp. z o.o.

- Tools supporting the oversight of documented information were refined;

- Efforts to enhance the RBI Management System were continued;

- The Food Safety Management System was maintained and improved;

- The International Sustainability & Carbon Certification System (ISCC EU) and the Sustainability Certification System for Biomass and Biofuels (KZR INiG) were improved and re-certified.

- Work was performed in pursuance of the IMS goals and objectives set forth in the following documents:

- ORLEN’s certified Integrated Management System was improved, which included expanding its scope to cover processes taken over from the former Grupa Lotos S.A. The system underwent a special audit and received the relevant IMS certificates.

- All the Management Systems operating within the PGNiG Branch Complex were certified, retaining their separate status (as systems excluded from the IMS operation), subject to the applicable rules in place at the Company.

Detailed information on the results of the activities carried out based on the Integrated Management System in 2022 is available in other parts of this Integrated Report, for example:

- For a description of the key environmental and climate impact indicators, see ‘Environment and climate’.

- For statistics demonstrating compliance with the highest safety standards, see ‘Occupational health and safety’.

- Data on the effects of customer health and safety activities is presented in ‘Development of the product and service portfolio and facilities for customers’.

- The results of energy management are described in ‘Energy management’.

- All certificates and policies are available at: Management systems | ORLEN.

Process-based management

ORLEN applies a process-based approach involving identification and mapping, based on an analysis of the context of the entire organisation’s operations, of the processes which are necessary to ensure compliance of its products and services offered to customers with relevant requirements, while maintaining pro-environmental production methods and a pro-environmental approach, and minimising the environmental impacts, continuously improving the safety of working conditions, and meeting requirements in all areas relevant to security of information processed by the Company.

The process sequence has been defined, as well as the relationships between the processes, which constitute a multi-layered mechanism that facilitates identifying and satisfying customer expectations. Individual processes are monitored and the achievement of their objectives is evaluated by checking process metrics and comparing them against adopted benchmarks. This approach allows us to manage and improve processes relying on real, measurable data.

In line with the risk-based approach, process owners are responsible for identifying threats (risks) and opportunities that can potentially affect the operation and efficiency of the processes – meeting customers’ requirements and taking appropriate and ‘adequate’ measures. A process-based system of internal audits is used, which operates in accordance with a dedicated procedure and checks compliance of individual areas with the adopted standards. The improvement measures we take cover internal and external factors and identify opportunities as they open to the organisation.

Any improvements to the Integrated Management System are decided on by the Company’s Senior Management, in line with the IMS evaluation procedure. The procedures in place specify how particular activities are to be carried out in each area.

A total of 54 processes/sub-processes were identified at the Company, for which 135 metrics were defined. The process charts specify the metrics, which include three-tiered criteria for evaluating effectiveness, defined as acceptable, requiring monitoring, or requiring corrective measures. The assessment of the delivery of the metrics is made on the basis of data entered by the process/sub-process owners into the Dok-system.

The precautionary principle, environmental damage prevention and effective workplace safety and information security management are ensured through standardisation and implementation of systemic mechanisms, which also include preventive measures. The precautionary principle is supported by systemic mechanisms that pre-emptively address potential irregularities and are based on process analysis and elements of risk and opportunity assessment. In accordance with the precautionary principle, business activities involve taking measures to prevent environmental degradation.

Audits − internal and external assurance of the Integrated Management System

In 2022, ORLEN was subject to periodic external audits. As a result, the Company obtained certificates of compliance with international standards for its activities.

The Company’s activities are assessed by accredited certification bodies, which audit the areas covered by the Management Systems in place on an annual basis.

In 2022, these included:

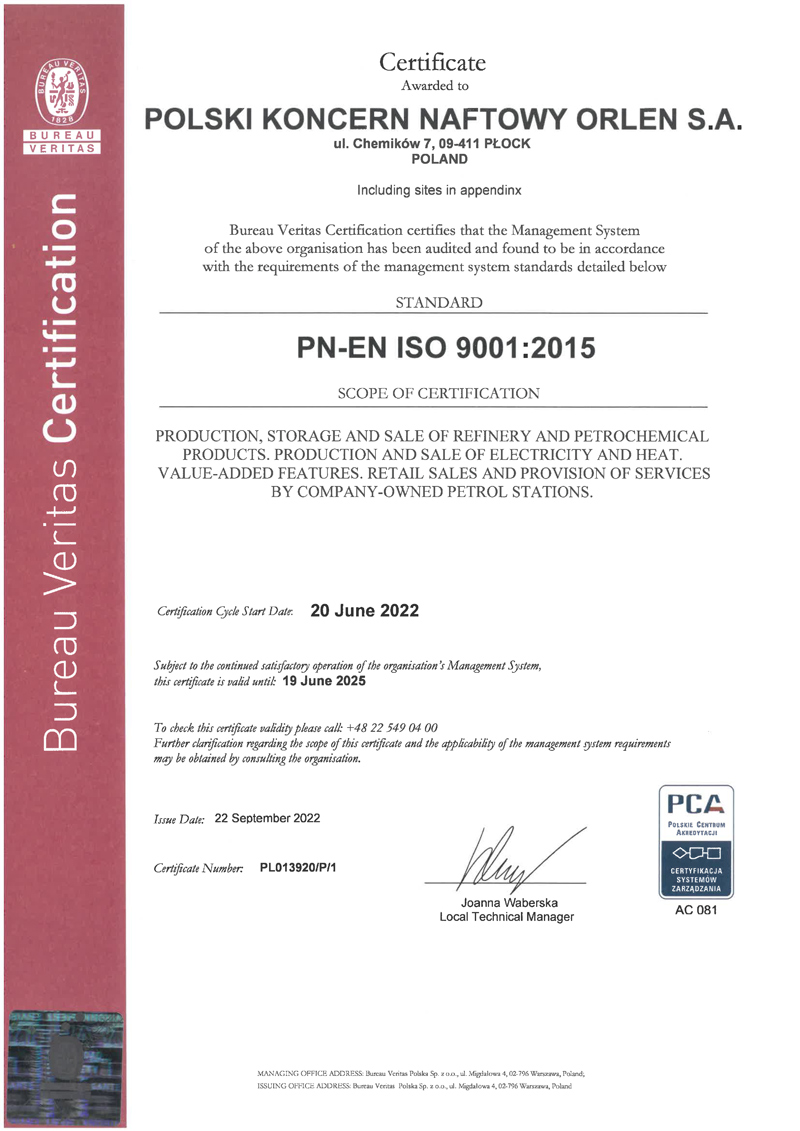

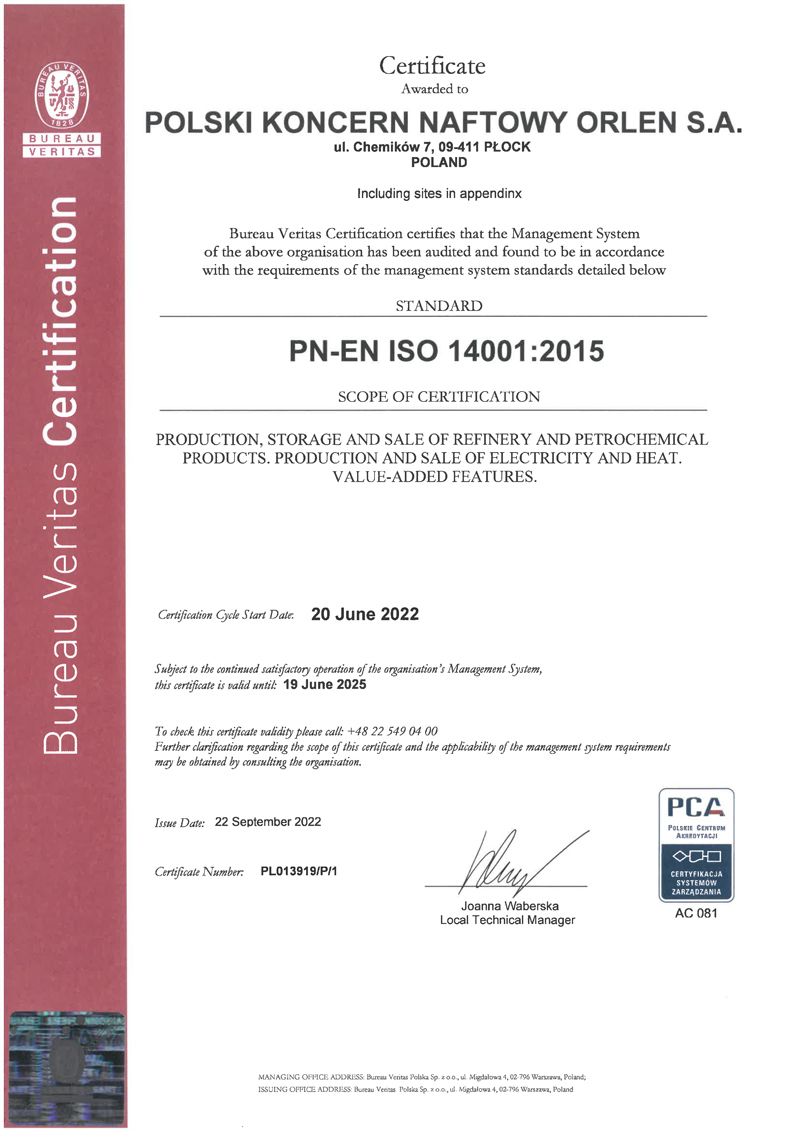

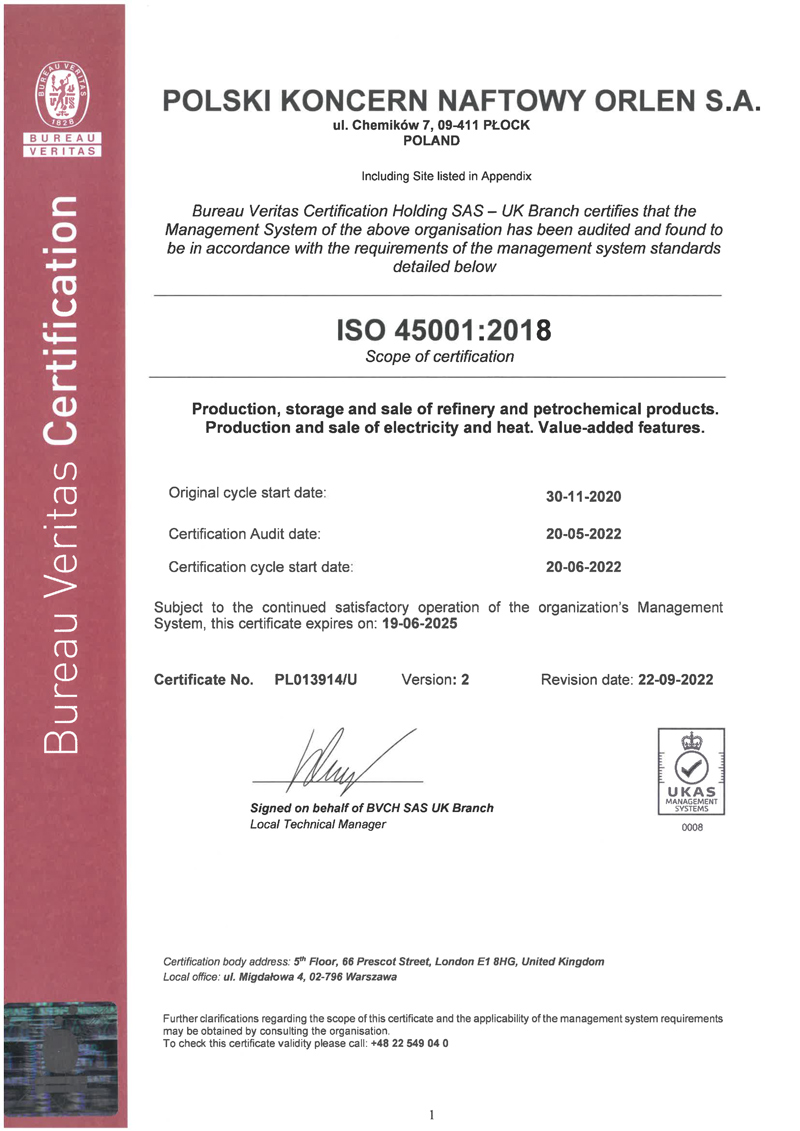

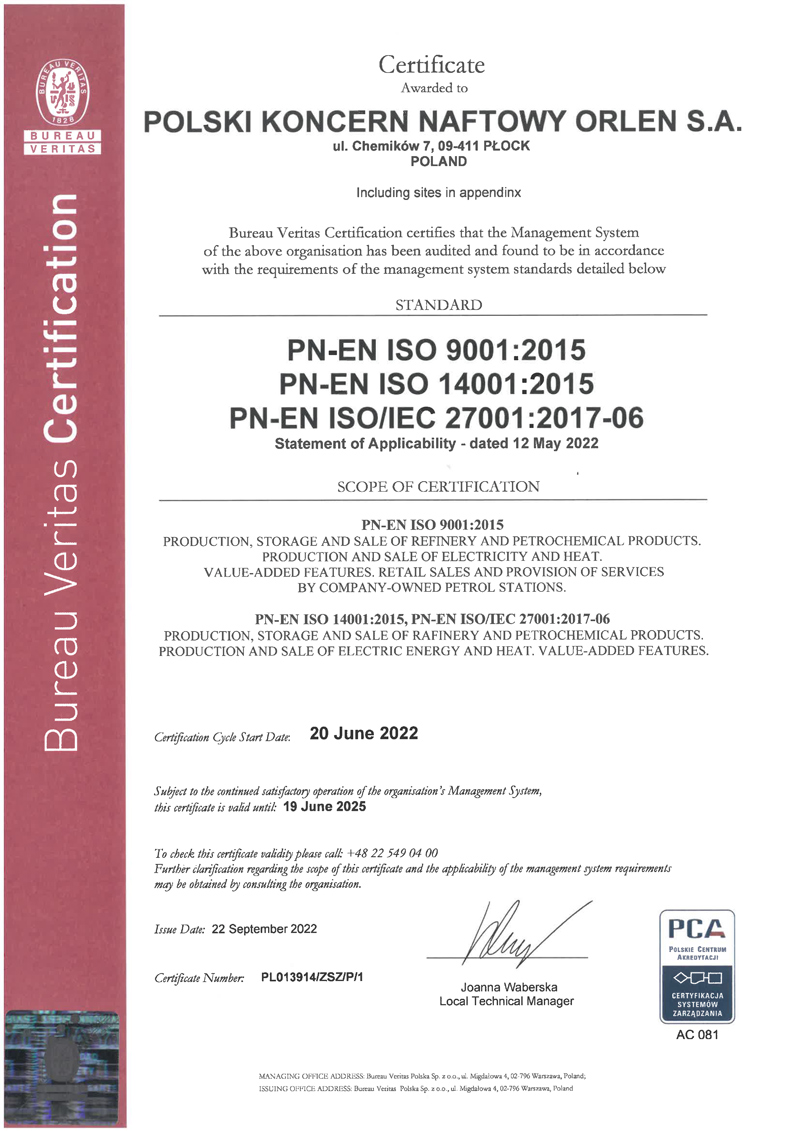

- IMS recertification audit by Bureau Veritas Poland – the on-site audit covered: selected Fuel Storage Terminals (Ostrów Wielkopolski, Świnoujście, Nowa Sól, Lublin), as well as the production plant and administrative units located in Płock. The audit identified no instances of non-compliance; the new certificates are valid through June 19th 2025.

- ISCC EU recertification audit by Bureau Veritas Polska (BVP), which included a review of the documentation confirming compliance of the ISCC EU system standards with the Renewable Energy Directive (RED) at the Management Systems Team, the Bio-component Procurement Team, the Offshore and Onshore Operations Department, the Fuel, Petrochemical and Bio-component Market Analysis Department, the C4 Derivatives Unit, the Blending Department and the Fuel Storage Terminals in Płock and Ostrów Wielkopolski. The audit found no instances of non-compliance and a certificate of compliance with the RED / ISCC EU Certification System was issued.

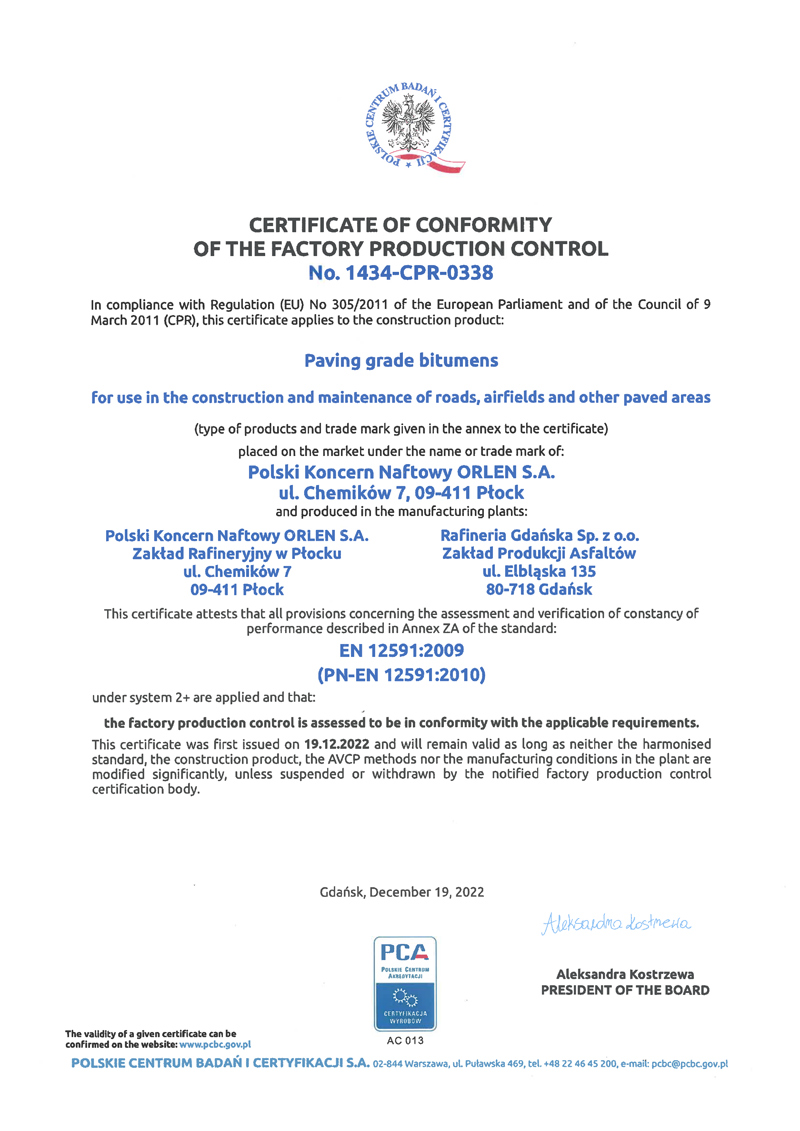

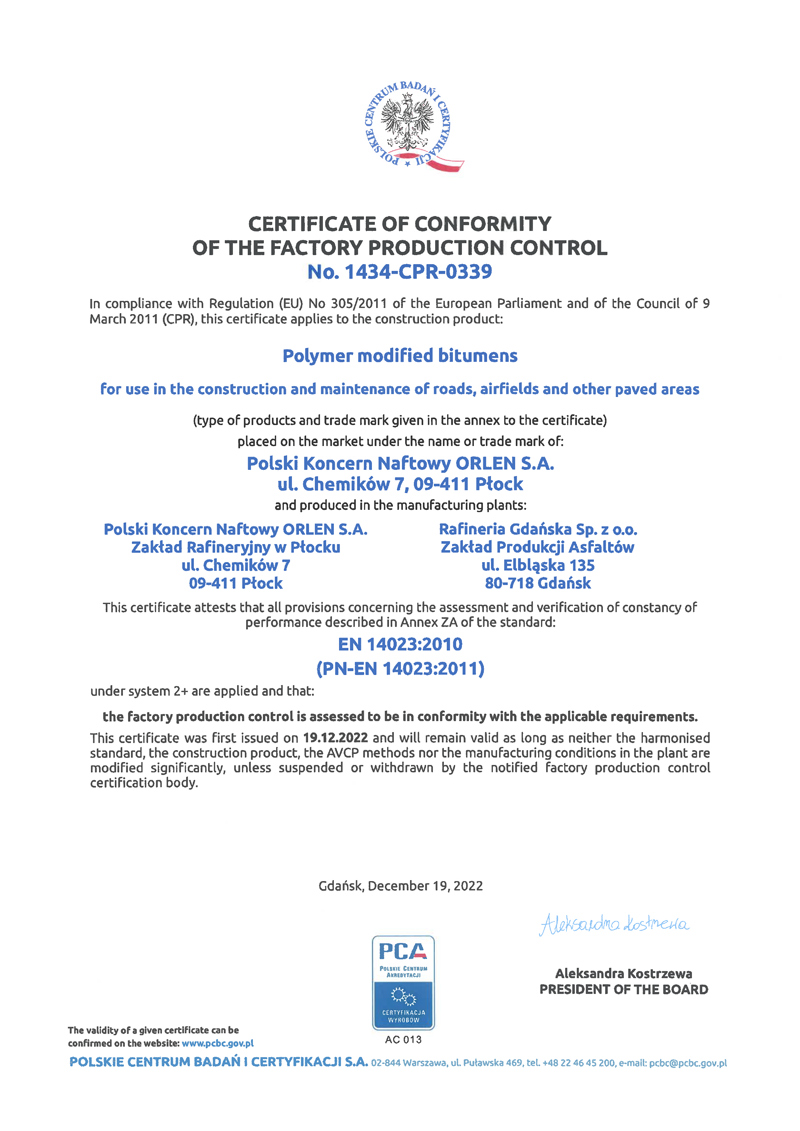

- Inspection of the Factory Production Control (ZKP) System by Polskie Centrum Badań i Certyfikacji (Polish Centre for Testing and Certification) carried out at Płock-based organisational units with regard to the manufacture and sale of road and polymer-modified bitumens. The audit identified no instances of non-compliance, no observations were made, and the compliance certificates for the ZKP system were maintained.

- AQAP 2110 recertification audit by the Quality Certification Centre of the Military University of Technology (MUT), covering the Płock-based organisational units involved in the manufacture and distribution of motor and aviation fuels. The audit revealed no instances of non-compliance and a new compliance certificate for the AQAP-2110 Quality Management System was issued, valid through July 9th 2025.

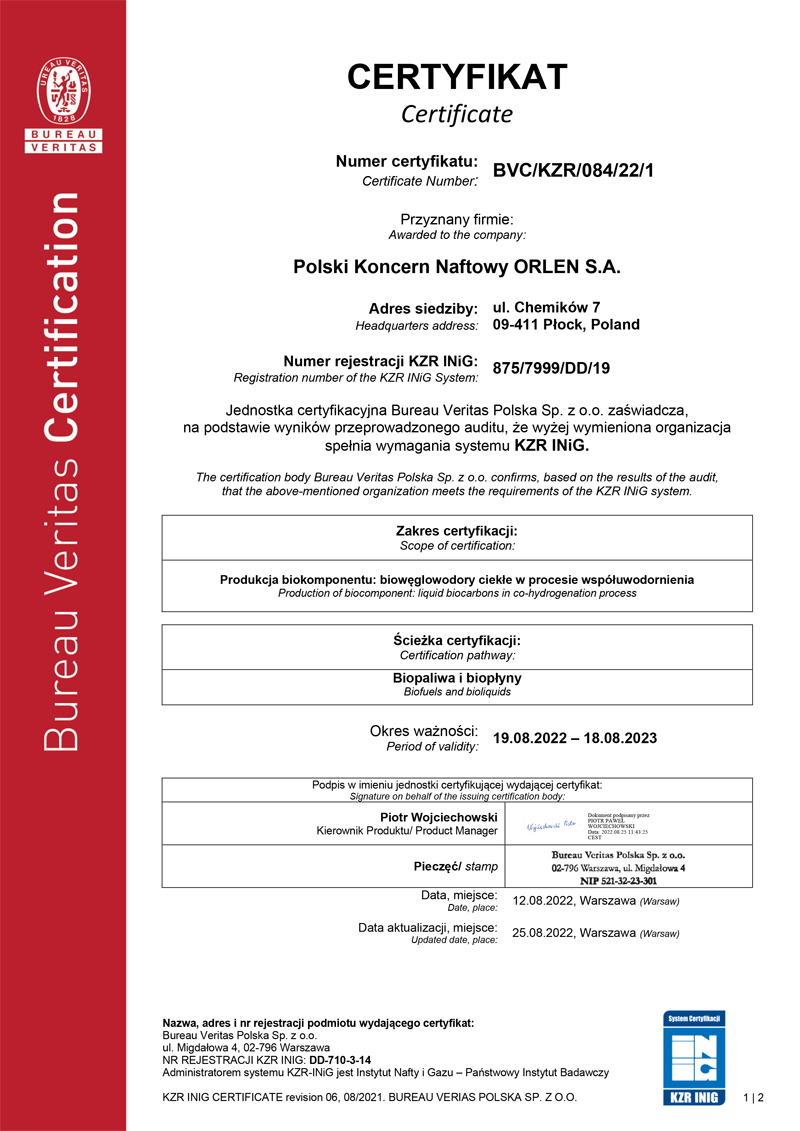

- KZR INiG system recertification audit by Bureau Veritas Polska, carried out as a hybrid process covering the production of a biocomponent: liquid bio-hydrocarbons in the co-hydrogenation process at Płock-based organisational units. The audit identified no instances of non-compliance and a new certificate was issued for the production of the bio-component: liquid bio-hydrocarbons in the co-hydrogenation process.

- ISO 50001 recertification audit by UDT-CERT – an on-site audit carried out in Płock and Włocławek. The audit revealed no instances of non-compliance and a new certificate, valid for another three years through December 5th 2025, was issued.

- Recertification audit by Bureau Veritas Polska (BVP) – a special audit of the Integrated Management System carried out following the merger of ORLEN and Grupa LOTOS S.A. The audit identified no instances of non-compliance, no observations were made and a recommendation was issued for ISO 9001, ISO 14001 and ISO 45001 certification. The scope of the ISO/IEC 27001 Certificate remained unchanged.

- ISCC special audit carried out by BVP following the merger with GL S.A. – scope of the ISCC certification extended to cover locations in Gdańsk, Czechowice-Dziedzice, Tychy and Szczecin.

- Product Audit for Aviation Fuels by the Air Force Institute of Technology (ITWL); the audit identified no instances of non-compliance, no observations were made and a recommendation was issued for the certification of our JET A-1 and F-34 aviation fuels.

The external audits identified no instances of non-compliance and confirmed correctness of the existing systems operation at ORLEN. Also, recommendations and new certifications were received.

Internal audit system

The audits confirmed compliance with the requirements of the applicable systems. The auditors also identified elements that required improvement.

In 2022, a total of about 520 internal audits of the Integrated Management System were planned and implemented, including:

445

32

10

7

23

7

12

The audits confirmed compliance with the requirements of the applicable systems. The auditors also identified elements that required improvement.

The certified Management Systems in place support:

- The organisation’s ability to meet customer needs and expectations (having a certificate is often a key formal condition for establishing a business relationship; access to domestic and international markets);

- Building the competitive advantage;

- Stronger reputation of the company and its products and services both among existing and prospective customers;

- Better organisation of internal documentation (a process-based approach helps to manage the organisation and eliminate inefficiencies);

- Confidentiality (access to information is limited to authorised personnel);

- Integrity (ensuring accuracy and completeness of information and the methods used);

- Availability (authorised users are given access to information and resources when needed);

- Improved quality (lower number of customer complaints);

- Earnings growth (because of lower internal costs achieved through improved quality that meets customer expectations);

- Enhancing environmental measures and contributing to environmental protection;

- Cost reductions achieved through lower energy consumption and lower waste volumes;

- Reduced risk of crisis (avoiding industrial accidents);

- Ensuring compliance with applicable requirements (avoiding penalties);

- Promoting pro-environmental thinking;

- Identification of threats to employees’ safety and prompt implementation of preventive measures;

- Engaging all employees in creating a safe workplace (cost reductions due to lower accident rates);

- Employees’ trust in the organisation and a sense of responsibility for its activities.

IMS documentation

Apart from the regulations contained in the System Books, the Integrated Management System currently includes 71 procedures:

- 7 Environmental Management System procedures;

- 3 procedures for AQAP 2120 requirements;

- 51 Quality Management System procedures;

- 2 Occupational Health and Safety Management System procedures;

- 5 Information Security Management System procedures;

- 1 Sustainability Certification System for Biomass and Biofuels procedure;

- 1 Energy Management System procedure;

- 1 procedure of the co-hydrogenation process certification system.

In 2022, the following were updated:

- Internal regulations on the Integrated Management System and Energy Management System operation;

- Integrated Management System Policy;

- Integrated Management System Book;

- Factory Production Control (ZKP) System Book;

- Energy Management System Book.

Following the merger, the scope of the Integrated Management System was expanded to cover processes taken over from the former GL S.A. The system underwent a special audit, as a result of which the scope of the certification was extended to cover processes carried out in Gdańsk.

In addition, all the Management Systems operating within the PGNiG Branch Complex were certified, retaining their separate status (as systems excluded from the IMS operation), subject to the applicable rules in place at the Company.

Management Systems at ORLEN Group companies

In 2022, the Group companies’ activities in relation to Integrated Management Systems were in line with the existing concept for the optimisation of the IMS functioning. The IMS policies are in place at the following key companies of the ORLEN Group: ORLEN, ORLEN Administracja, ANWIL, Basell ORLEN Polyolefins, ORLEN Laboratorium, ORLEN Eko, ORLEN Asfalt, ORLEN Serwis, ORLEN Upstream, IKS Solino, ORLEN KolTrans, ORLEN Oil, ORLEN Aviation, ORLEN Paliwa, ORLEN Projekt, ORLEN Budonaft, ORLEN Lietuva, ORLEN Unipetrol Group, ORLEN Centrum Usług Korporacyjnych, ORLEN Południe, ORLEN Centrum Serwisowe, and ORLEN Ochrona. In addition, collaboration on Management Systems was initiated with RUCH, and closer cooperation with the Energa Group in this area is being considered.

The Integrated Management Systems were built based on the following standards:

- Quality Management Systems compliant with ISO 9001:2015 and AQAP 2110;

- Environmental Management Systems compliant with ISO 14001:2015;

- OHS Management Systems compliant with ISO 45001:2018;

- Information Security Management Systems compliant with ISO/IEC 27001:2017-06;

- Energy Management System compliant with PN-EN ISO 50001: 2018-09.

Depending on business needs, the companies maintain the certificates for the systems indicated above. In addition, depending on the business profiles, legal requirements, Customer expectations, etc., some companies have implemented the following systems in their organisations: AQAP 2110 Management System, Factory Production Control, Rail Transport Safety Management System (SMS), Rail Transport Maintenance Management System (MMS), Quality Management System for Welding Processes, HACCP Food Safety Management System, ISCC EU System, KZR INiG System, ISO/IEC 17025 Laboratory Quality Management System. Where appropriate, a relevant certification or registration was secured.

2022 was the year when ORLEN merged with the LOTOS and PGNiG Groups, which required actions beyond the standard procedures. The companies smoothly adapted to modified rules of supervision of the Management Systems, as confirmed by the results of special audits and successful certification processes.

Management Systems

According to ORLEN's strategy, our task in the product quality area is to address the needs and expectations of Customers. The ORLEN Group’s goal and ambition is to retain our position of quality leader in the Polish and international markets. The focus is on strengthening Customer confidence in ORLEN as a company offering top-class quality, environmentally-friendly solutions, and timely delivery of the products we manufacture and sell.

Being aware of our environmental impact, we commit to gradually bring our process planning and execution methods in line with the sustainability requirements by adopting an integrated approach to the pollution prevention and environmental protection processes.

In accordance with applicable laws and in keeping with our Integrated Management System Policy, we protect the life and health of all our employees by building a safe and healthy working environment for them.

The above objectives and activities are pursued based on our Integrated Management System, which comprises the following systems: ISO 9001 Quality Management System, AQAP 2110 Quality Management System, ISO 14001 Environmental Management System, ISO 45001 Occupational Health and Safety Management System, PN-ISO/IEC 27001 Information Security Management System, HACCP Food Safety Management System, ISCC EU and KZR INiG certification systems for sustainable biofuels, bioliquids, and biocomponents production, and Factory Production Control (ZKP).

The systems meet the highest international management standards and are applied by ORLEN in its day-to-day operations to ensure professional customer service and maintain top health and environmental protection standards.

ISO 9001 Quality Management System

The Group’s dedication to providing best quality products that meet Customer expectations is reflected in the Quality Management System and the Integrated Management System Policy implemented within its framework. The system was first certified in 1996 and then re-certified in 1999 by Bureau Veritas Quality International and Polskie Centrum Badań i Certyfikacji (Polish Centre for Testing and Certification). The Quality Management System was improved in the following years. Currently, we hold a certificate of compliance with the requirements of PN-EN ISO 9001:2015-10 issued by BV Poland.

AQAP 2110 Quality Management System

ORLEN holds a certificate of compliance with the requirements of the AQAP 2110 standard for the production and wholesale of motor and aviation fuels. It is an important element necessary to attract and retain military customers in NATO countries.

ISO 14001 Environmental Management System

Implementation of the Environmental Management System confirms that the overriding objective of the ORLEN’s strategy is to achieve, as far as practicable, a neutral impact on our immediate environment and to minimise the environmental impact of the use of our products.

ISO 45001 OHS Management System

The main purpose of the OHS Management System is to support efforts to improve occupational health and safety by defining the requirements for an effective and efficient management system based on legal regulations, hazard identification, assessment of occupational risk and health and safety risks and opportunities. The key message declared in the Integrated Management System Policy is that every employee has the right to safe and healthy working conditions, which the organisation is obliged to provide.

ISO/IEC 27001 Information Security Management System

ORLEN’s Information Security Management System was first certified for compliance with the requirements of the PN-I-07799-2 standard in May 2007, by Bureau Veritas Certification. Currently, the system meets the requirements of PN-EN ISO 27001, ensuring confidentiality, integrity and availability of information. Information security is not only a business necessity, which ensures efficient operation of the organisation by providing well-structured information processing, but also a legal obligation. The key purpose of the system is to maintain and improve information security management, thus minimising the risk of an incident and its adverse impact on our operations and activities, by deploying technical and organisational measures that provide the maximum level of security of data processing, protecting data against unauthorised access, breach of confidentiality or loss of integrity, or theft.

ISO 50001 Energy Management System

ORLEN has implemented the ISO 50001 Energy Management System (SZEn) in response to the National Action Plan for energy efficiency developed under the Energy Efficiency Act of May 20th 2016, in accordance with Directive 2012/27/EU as amended by Directive 2018/2002 on energy efficiency. Efficient energy management is not only a source of benefits to a business, but also a legal requirement that is most easily met with ISO 50001 – a standard that sets globally recognised best practices for energy management. The Energy Management System is also an element of the ORLEN 2030 strategy. The vision for the ORLEN Group’s growth through commitment to low-carbon energy and increased use of alternative fuels, in line with sustainable development principles, helps enhance Poland’s energy security. In 2022, the Energy Management System was successfully re-certified for 2022-2025.

ISCC EU certification system

The legal basis for the operation of sustainable development systems is the EU Directive on the Promotion of the Use of Energy from Renewable Sources (RED).

REDII (Directive 2018/2001) provides a general climate framework for 2020–2030, including a 2030 target of at least a 27% share of renewable energy in the EU’s energy consumption. The Directive recasts and repeals previous legislation (Directive 2009/28/EC, Directive (EU) 2015/1513 and Council Directive 2013/18/EU).

Certificates

KZR INiG certification system

In accordance with the Act on Biocomponents and Liquid Biofuels, entities operating in the field of production of bio-components, processing of biomass, purchase, import or intra-Community purchase of biomass or bio-components which are to be counted towards the National Indicative Target, are obliged to obtain a certificate confirming that they fulfil the sustainability criteria.

HACCP Food Safety Management System

In order to satisfy the requirements of food law and the basic assumptions of the Codex Alimentarius, ORLEN has implemented the HACCP Food Safety Management System at its service stations. As the range of our food and drink services expands and the regulatory requirements change, the HACCP system is being continuously improved and developed. To ensure the best quality of its food products and services, ORLEN has drafted and communicated the Food Safety Policy.

Factory Production Control (ZKP)

Since January 2nd 2015, ORLEN S.A. has been a manufacturer of building products. Pursuant to Regulation (EU) No. 305/2011 of the European Parliament and of the Council of March 9th 2011, ORLEN is required to maintain a Factory Production Control (ZKP) system.

Compliance system at the ORLEN Group

The objective of the ORLEN Group’s Compliance System is to implement and continuously improve a coherent set of legal and organisational solutions aimed at ensuring compliance of all business processes across the ORLEN Group with mandatory and voluntary requirements that ORLEN Group companies have undertaken or decided to comply with in order to avoid legal, financial and reputational consequences that may be incurred by ORLEN Group companies, management and employees in the event of a compliance breach.

Read also:

Short-cuts:

ORLEN Group 2022 Integrated Report

You can also download the report in PDF format